crushing deep cavity jaw crusher

2019-08-13T12:08:41+00:00

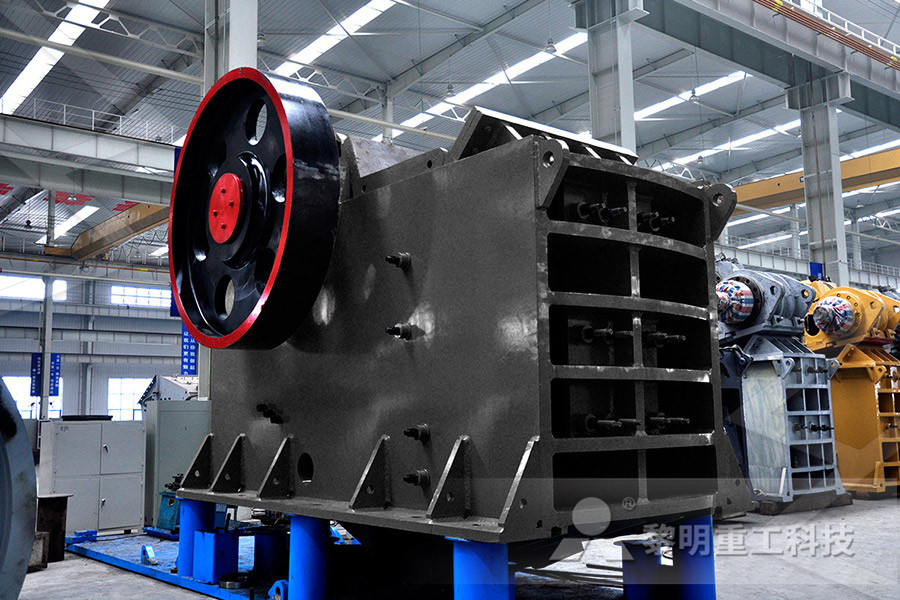

Jaw Crusher (Deep Cavity) machinerymining

Jaw Crusher (Deep Cavity) PE series jaw crusher is a new type of crushing machine developed by Dingbo Its crushing cavity consists of movable jaw plate and fixed jaw plate It has the advantages of simple structure, reliable work, easy maintenance and low construction cost This crusher is widely used for crushing all kinds of ores and bulk CGE Jaw Crusher CGE Jaw Crusher is a kind of deep cavity compound pendulum jaw crusher, produced by using advanced foreign technology It is one of the most commonly used crushers in the mining and quarry industry and is widely used in primary and secondary crushing of various kinds of stones and rocks with compressive strength less than 350MPaCGE Jaw Crusher trustoncrusherdurable and efficient deep cavity jaw crusher for crushing Flexible discharge opening setting of jaw crusher allows perfect match with relative equipments crushing cavity is deep and there is no dead area,which improves feeding capacity and output high reduction ratio and high crushing ratioThe final particles is uniform spacing piece type dischargehole adjustment device is durable and efficient deep cavity jaw crusher for crushing

Crushing 101 – Different types of crushers for distinctive

Dec 17, 2020 The very first crushers invented were jaw crushers, which are built to reduce the size of large materials and operate with high volume in primary crushing Their main purpose is to reduce the material to a small enough size that it can be transported to the next crushing StanHeph is the proprietary owner of a concept called Deep Throat Crushing This encompasses a combination two in one and three in one process The combination Deep Throat Jaw Crusher will crush Primary and Secondary material in one pass All our Jaw Crushers, crush to a StanHeph – CRUSHING ENGINEERING CONSULTINGWe specialize in research and development and sales of mining machinery and crushing production lines The company's main business is various crushing equipment, including ore crusher equipment, mobile crushing station equipment, cone crusher and special material crushing equipment such as construction waste equipment 1durable and efficient deep cavity jaw crusher for crushing

Engineered for the toughest feed materials ® C

With a good grip, the jaw crusher can crush rocks efficiently through the entirety of the cavity, and the nip angle can be further improved with an intermediate plate Optimal design reduces operational and wear costsJaw Crushers have two types: PE and PEX series PE series jaw crusher, widely used in theprimary crushing process, with a capacity of 1800tph, feeding size 1251000mm, output size10350 mm, which is suitable for the production of various soft and hard materials It is the ideal choice for stone primary crushing processPE Series Jaw Crusher Dewo MachineryJaw Crusher (Deep Cavity) PE series jaw crusher is a new type of crushing machine developed by Dingbo Its crushing cavity consists of movable jaw plate and fixed jaw plate It has the advantages of simple structure, reliable work, easy maintenance and low construction cost This crusher is widely used for crushing all kinds of ores and bulk Jaw Crusher (Deep Cavity) machinerymining

Jaw crusher

PE type is used for primary crushing, and PEX type is used for secondary and fine crushing Features and technology advantages of jaw crusher 1 Deep crashing cavity, no unreachable corner in cavity, higher feeding capacity and productivity 2 Great crushing ratio, homogeneous output size 3May 13, 2014 website:cscrusher TRUSTON CGE Jaw Crusher (1) Chamber of crusher is designed to have deep cavity, the main parts of the body using wedge weldiCGE Jaw Crusher YouTubeDec 17, 2020 In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes a compressive action A double toggle crusher has two shafts and two toggle plates The material is reduced in a crushing cavity, between an external fixed element, a bowl liner, and an internal moving Crushing 101 – Different types of crushers for distinctive

PEX Jaw CrusherGrinding Mill,Stone Crusher Machine,Sand

Product description of PEX series deep cavity jaw crusher Jaw crusher series have features of big crushing ratio, uniform products size, simple structure, reliable work, easy maintenance and low cost It is widely used in stone mining, metallurgy industry, building material, highway, railway, water conservancy and chemical industriesOur Photos for Jaw Crusher: Features: 1 Optimized deep cavity structure and reasonable running parameters of movable jaw greatly increase the equipment capacity and its crushing ratio; 2 Adopting compound pendulum principle, the equipment is simple in structure, stable in performance, easy in operation and maintenance; 3Jaw Crusher for Crushing Stone EB CastworldStanHeph is the proprietary owner of a concept called Deep Throat Crushing This encompasses a combination two in one and three in one process The combination Deep Throat Jaw Crusher will crush Primary and Secondary material in one pass All our Jaw Crushers, crush to a standard 8:1 ratioStanHeph – CRUSHING ENGINEERING CONSULTING

Jaw Crusher High Standard Cruhser Manufacturer and

Aug 01, 2019 Jaw crusher is the most effective equipment for crushing harder ore It has advanced design and optimized performance In addition, it has simple maintenance and long service life The crusher adopts the deep and symmetrical crushing chamber, which is easy to adjust with a PE Jaw Crusher Introduction Jaw Crushers have two types: PE and PEX series PE series jaw crusher, widely used in theprimary crushing process, with a capacity of 1800tph, feeding size 1251000mm, output size10350 mm, which is suitable for the production of various soft and hard materials It is the ideal choice for stone primary crushing PE Series Jaw Crusher Dewo Machineryaspect when considering the performance of a jaw crusher Our industryleading stroke is amplified from top to bottom, being at its longest in the lower parts of the cavity This increases the open area between the jaw dies allowing the material to have more space to get out, while also enabling interparticle crushing This design principleEngineered for the toughest feed materials ® C

Crushing and Screening Solutions Catalogue

*) Crusher without options **) Crusher with options ***) Actual feed opening depths are cavity specific ® C Series™ jaw crushers are delivered with lifting tools for jaw dies and cheek plates In addition, an optional Maintenance platform makes wear part change safe and easy Open the CGE Jaw Crusher CGE Jaw Crusher is a kind of deep cavity compound pendulum jaw crusher, produced by using advanced foreign technology It is one of the most commonly used crushers in the mining and quarry industry and is widely used in primary and secondary crushing of various kinds of stones and rocks with compressive strength less than 350MPaCGE Jaw Crusher trustoncrusher® C120™ jaw crusher is generally used as primary crusher, as the first step of size reduction It prepares the feed for the secondary crusher in a crushing and screening process However, due to its versatility, ® C120™ jaw crusher can be utilized in later stages of the crushing process as well, depending on the application and processed material ® C120™ jaw NORDBERG® C120™ JAW CRUSHER Pilot Crushtec

Jaw Crusher qxdali

1 The crusher’s movable jaw assembly is advanced and durable 2 The crushing ratio of deep cavity is large, the cavity shape is optimized, and the crushing efficiency is high 3 The jaw plate is arcshaped, and the effective length of the jaw plate increases, which CGE Jaw Crusher CGE Jaw Crusher is a kind of deep cavity compound pendulum jaw crusher, produced by using advanced foreign technology It is one of the most commonly used crushers in the mining and quarry industry and is widely used in primary and secondary crushing of various kinds of stones and rocks with compressive strength less than 350MPaCGE Jaw Crusher trustoncrusherMay 13, 2014 website:cscrusher TRUSTON CGE Jaw Crusher (1) Chamber of crusher is designed to have deep cavity, the main parts of the body using wedge weldiCGE Jaw Crusher YouTube

Jaw Crusher qxdali

1 The crusher’s movable jaw assembly is advanced and durable 2 The crushing ratio of deep cavity is large, the cavity shape is optimized, and the crushing efficiency is high 3 The jaw plate is arcshaped, and the effective length of the jaw plate increases, which Our Photos for Jaw Crusher: Features: 1 Optimized deep cavity structure and reasonable running parameters of movable jaw greatly increase the equipment capacity and its crushing ratio; 2 Adopting compound pendulum principle, the equipment is simple in structure, stable in performance, easy in operation and maintenance; 3Jaw Crusher for Crushing Stone EB CastworldProduct description of PEX series deep cavity jaw crusher Jaw crusher series have features of big crushing ratio, uniform products size, simple structure, reliable work, easy maintenance and low cost It is widely used in stone mining, metallurgy industry, building material, highway, railway, water conservancy and chemical industriesPEX Jaw CrusherGrinding Mill,Stone Crusher Machine,Sand

Jaw Crusher RMB Knovatech Pvt Ltd

PE series is used in primary crushing PEX series is used in secondary crushing and fine crushing Features and technology advantages Simple structure, easy maintenance, stable function, low operation cost, great crushing ratio Deep crashing cavity, no unreachable corner in cavity, higher feeding capacity and productivityStanHeph is the proprietary owner of a concept called Deep Throat Crushing This encompasses a combination two in one and three in one process The combination Deep Throat Jaw Crusher will crush Primary and Secondary material in one pass All our Jaw Crushers, crush to a standard 8:1 ratioStanHeph – CRUSHING ENGINEERING CONSULTING® C120™ jaw crusher is generally used as primary crusher, as the first step of size reduction It prepares the feed for the secondary crusher in a crushing and screening process However, due to its versatility, ® C120™ jaw crusher can be utilized in later stages of the crushing process as well, depending on the application and processed material ® C120™ jaw NORDBERG® C120™ JAW CRUSHER Pilot Crushtec

PE Series Jaw Crusher Dewo Machinery

PE Jaw Crusher Introduction Jaw Crushers have two types: PE and PEX series PE series jaw crusher, widely used in theprimary crushing process, with a capacity of 1800tph, feeding size 1251000mm, output size10350 mm, which is suitable for the production of various soft and hard materials It is the ideal choice for stone primary crushing *) Crusher without options **) Crusher with options ***) Actual feed opening depths are cavity specific ® C Series™ jaw crushers are delivered with lifting tools for jaw dies and cheek plates In addition, an optional Maintenance platform makes wear part change safe and easy Open the Crushing and Screening Solutions Catalogue Jaw Crushers are used to reduce the size of many different types of materials in many applications The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a doubletoggle Jaw Crusher Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw CrushersJaw Crushers McLanahan

Mining Equipment Crushing, Screening, Grinding Machine

Jaw Crusher (Deep Cavity) PE series jaw crusher is a new type of crushing machine developed by Dingbo Its crushing cavity consists of movable jaw plate and fixed jaw plate READ MORE; Impact CrusherDescription A Laboratory Jaw Crusher engineered for precrushing of extremely hard up to brittle materials The 4″ x 5″ 911MPEJC100 Jaw Crusher is designed for batch and continuous crushing of middle hard, hard brittle and tough materials for the following fine grinding Principle of operation of this crusher The Model 100 mm X 130 mm 911MPEJC100 Jaw Crusher is used by laboratories and Laboratory Jaw Crusher 911MetallurgistMobile crusher is mainly used in hard rock crushing ,aggregate production , outdoor mining crushing,construction waste recycling, cement production and tunnel crushing Working principle: Equipment consists of: vibrating feeder, jaw crusher, or deep cavity "stone at stone" impact crusher, vibrating screen, foldable belt conveyorHot sale Mobile impact crusher,Mobile crushing plant in china